March 5-7, 2024

PARIS-NORD VILLEPINTE

Functionally enhanced,

process optimized,

value bonded

Discover a new way to develop the most advanced, efficient & sustainable composite materials and adhesive joints.

Explore our capabilities and case studies

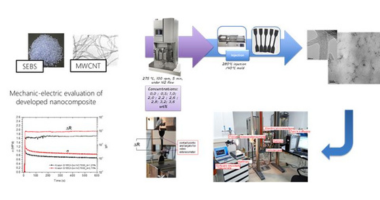

01/ DESIGN & DEVELOPMENT OF MATERIAL

We create new materials with tailored properties, optimizing the material's physical - chemical properties to meet specific application requirements. Our aim is to leverage the synergy between fibers, matrices and bonding agents to achieve the desired preformance characteristics.

Levis project:

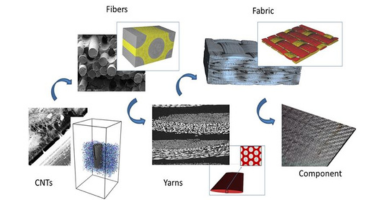

02/ COMPUTATIONAL MATERIALS

We use computer models to predict material properties, including composites and adhesives, before prototyping. This method explores extensive material spaces, optimizing structures at various scales and accelerating the development of new materials with desired properties.

Iclimabuilt project:

03/ MATERIAL CHARACTERIZATION

We apply several techniques to analyze and measure the physical - chemical properties of a material. This process is critical for understanding the material's structure-function relationships guiding the design and optimization of new materials for specific applications. Techniques can range from microscopy and spectroscopy to mechanical testing and thermal analysis.

Ambiance project:

04/ DIGITAL TWINS & PROCESS TRANSFORMATION MODELLING

We are able to create virtual replicas of physical materials and processes, allowing the simulation, analysis, and optimization of material behaviors and transformation processes in a digital environment. This approach enables the prediction of how materials will respond under different conditions, how to optimize manufacturing processes and the optimization of performance features for the final application.

Caelestic project:

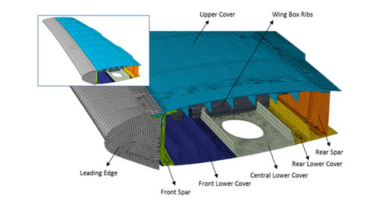

05/ VIRTUAL PROTOTYPES

We can create digital models of products or materials before physical prototypes are manufactured. This technique allows designers and engineers to simulate and analyze the behavior and performance of a product in a computer-generated environment, with different boundary conditions and loads, reducing development costs, and shortening time-to-market by identifying and addressing issues early in the development process.

Genex project:

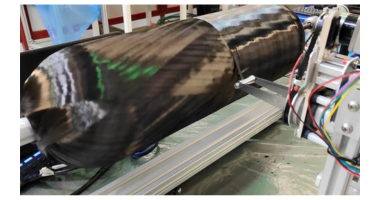

06/ TEST & EXPERIMENTATION FACILITY IN COMPOSITES & ADHESIVE JOINTS

TEF in composites and adhesives. We offer a combination of physical and virtual facility in which technology providers can get primarily technical support to test their latest AI-based software and hardware technologies (including AI-powered robotics) in real-world environments. We can work with in a wide field of composite materials manufacturing processes, always out-of-autoclave.

Ai-Matters project:

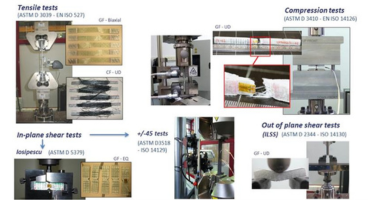

07/ STRUCTURAL INTEGRITY TEST LABORATORY

Structural Integrity Test Laboratory. In our facilities we are specialized in assessing the durability, strength, and longevity of materials and structures under various conditions and loads. This includes testing for fatigue, fracture, stress, corrosion, and impact resistance to ensure that materials, such as composites and metal alloys, and structures meet rigorous safety and performance standards. We employ a range of experimental setups and analytical techniques to simulate real-world stresses and environmental conditions, providing essential data for the design, improvement, life extension and certification of structural components

Carbo4Power project:

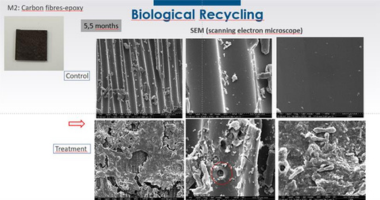

08/ END-OF-LIFE & RECYCLING

In our End-of-Life and Recycling Laboratory we work on the study and development of processes for the disposal, recycling, and repurposing of composite materials and adhesives at the end of their useful life. This laboratory conducts research on sustainable dismantling techniques, recycling methods (mechanical, chemical and biochemical), and the environmental impact assessment of waste materials. Its goal is to create efficient and environmentally friendly solutions for recovering valuable materials, reducing waste, and promoting the circular economy by transforming end-of-life materials into new resources for manufacturing and other applications.

Eurecomp project: